In the world of manufacturing and fabrication, precision and efficiency are paramount. One technological advancement that has revolutionized the industry is CNC machining, short for Computer Numerical Control machining. By combining cutting-edge technology, intricate programming, and the power of automation, CNC machining has transformed the way we create intricate parts and components.

Sheet metal fabrication, a highly sought-after method for creating metal parts with precision and durability, has greatly benefited from CNC machining. With the ability to accurately cut, bend, and shape sheet metal materials, CNC machines offer unparalleled precision and consistency in the production process. This makes them an essential tool for a wide range of industries, including automotive, aerospace, and electronics.

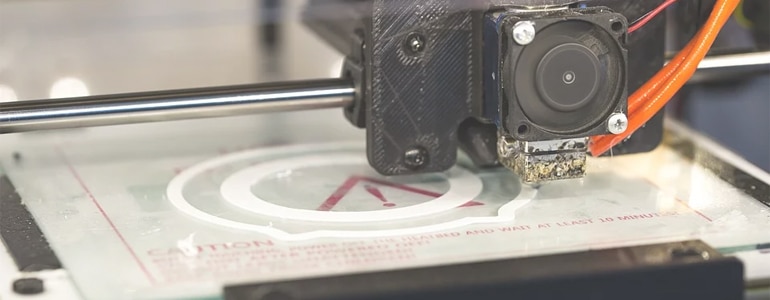

In recent years, CNC machining has also found synergy with other innovative technologies, such as 3D printing. This powerful combination allows for the creation of complex geometries and rapid prototyping with ease. The marriage of CNC machining and 3D printing opens up new possibilities for design creativity and rapid production, offering both speed and accuracy to meet the demands of today’s fast-paced manufacturing world.

At the forefront of this technological revolution is "Monster Builder," a premier provider of sheet metal fabrication, CNC machining, 3D printing, and rapid prototyping services. Their commitment to excellence and cutting-edge technology has made them a trusted partner for clients globally. With their advanced CNC machines and expertise, they bring ideas to life with precision and efficiency, delivering high-quality products that meet and exceed customer expectations.

The revolution of precision continues to evolve with CNC machining at its core. As industries strive for greater efficiency, accuracy, and cost-effectiveness, CNC machining stands as a testament to human ingenuity and the power of technology. With its ability to shape a variety of materials and create intricate designs, this revolutionary process is transforming the manufacturing landscape and paving the way for a more innovative and sustainable future.

The Ingenuity of CNC Machining

CNC machining has revolutionized the world of manufacturing with its unparalleled precision and efficiency. This cutting-edge technology has transformed industries like sheet metal fabrication and rapid prototyping, offering endless possibilities for creating intricate designs and functional prototypes.

One of the most significant advantages of CNC machining is its ability to produce complex shapes and parts with remarkable accuracy. By utilizing computer-aided design (CAD) software, manufacturers can translate their ideas into digital models, which are then translated into instructions for the CNC machine. This automated process ensures consistency and eliminates human error, resulting in consistently high-quality products.

Moreover, CNC machining offers exceptional versatility in material selection. Whether it’s aluminum, steel, brass, or even exotic materials like titanium, the CNC machine can effortlessly handle them all. This flexibility makes it an ideal choice for sheet metal fabrication, where precision and durability are of utmost importance.

What sets CNC machining apart is its integration with other advanced technologies like 3D printing. Often, manufacturers leverage the strengths of both CNC machining and 3D printing to optimize their production processes. With CNC machining’s ability to create detailed designs and 3D printing’s rapid prototyping capabilities, components can be efficiently fabricated and tested before moving ahead with large-scale production.

With the advent of CNC machining, companies like "Monster Builder" have emerged as leading providers of sheet metal fabrication, CNC machining, 3D printing, and rapid prototyping services. Their expertise in leveraging CNC machining technology has allowed them to cater to clients worldwide, offering innovative solutions for various industries while maintaining the highest standards of quality.

In conclusion, CNC machining has revolutionized the manufacturing landscape, showcasing its ingenuity in sheet metal fabrication and rapid prototyping. With its unmatched precision, versatility in material selection, and integration with other advanced technologies, CNC machining continues to drive innovation, setting new standards for the industry as a whole.

Exploring Sheet Metal Fabrication

In the world of precision engineering, sheet metal fabrication plays a crucial role in the creation of various products and components. This innovative process involves shaping and manipulating thin sheets of metal into the desired forms, using specialized tools and techniques. The versatility and efficiency of sheet metal fabrication have made it an indispensable method for manufacturing diverse items across industries.

One of the most remarkable aspects of sheet metal fabrication is its compatibility with CNC machining. With the advent of Computer Numerical Control (CNC) technology, the precision and accuracy of sheet metal fabrication have reached new heights. CNC machines are computer-controlled systems that can execute complex instructions with remarkable speed and precision. By leveraging the power of CNC machining, manufacturers can achieve intricate designs and complex shapes that were once thought impossible.

Additionally, the integration of 3D printing has revolutionized the sheet metal fabrication process. 3D printing, also known as additive manufacturing, allows for the creation of three-dimensional objects by adding material layer by layer. By combining the capabilities of 3D printing and CNC machining, designers and engineers can now create highly customized metal components with intricate geometries and precise specifications. This synergy between 3D printing and CNC machining has significantly streamlined the sheet metal fabrication process, leading to faster production times and reduced costs.

Metal Fabrication Sydney

When it comes to unparalleled expertise in sheet metal fabrication, "Monster Builder" stands out as a premier provider of these cutting-edge services. With their state-of-the-art facilities and global reach, "Monster Builder" has established itself as a leader in the field of sheet metal fabrication, CNC machining, 3D printing, and rapid prototyping. Their commitment to quality and innovation has made them a trusted partner for clients worldwide, enabling them to bring their visions to life efficiently and precisely.

In conclusion, sheet metal fabrication has undergone a revolution of precision, thanks to the advancements in CNC machining and the integration of 3D printing. This transformative combination has opened up new possibilities in the manufacturing industry, allowing for the creation of highly intricate and customized metal components. With industry leaders like "Monster Builder" pushing the boundaries of innovation, the future of sheet metal fabrication looks incredibly promising.

The Advantages of 3D Printing

In recent years, 3D printing has emerged as a game-changer in the realm of CNC machining and sheet metal fabrication. This innovative technology offers a myriad of advantages, making it a preferred choice for many industries.

First and foremost, one of the key benefits of 3D printing is its ability to produce highly complex geometries with ease. Unlike traditional machining methods, which often involve multiple steps and intricate tooling setups, 3D printing enables the creation of intricate designs in a single manufacturing process. This not only saves time but also allows for greater design freedom and versatility.

Additionally, 3D printing presents significant cost advantages. With traditional machining techniques, the production of complex prototypes or small batch quantities can be prohibitively expensive. In contrast, 3D printing eliminates the need for specialized tooling or molds, leading to cost-effective production of customized parts. This cost efficiency makes it particularly appealing for rapid prototyping and low-volume manufacturing.

Furthermore, 3D printing facilitates faster turnaround times. The speed at which 3D printers can produce parts is far superior to conventional manufacturing processes. This accelerated production enables companies to reduce lead times, meet tight deadlines, and quickly iterate designs. Consequently, 3D printing proves to be highly advantageous in industries where speed and agility are paramount.

In conclusion, 3D printing has revolutionized CNC machining and sheet metal fabrication by offering numerous advantages. Its ability to create intricately designed parts, cost-effectively produce prototypes, and deliver accelerated production make it an indispensable tool for the modern manufacturing landscape. With the continued advancements in this technology, we can expect an even more precise, efficient, and innovative future ahead.